Overview of Akura™ 96 Spheroid Microplate

Automation compatible – Secure handling – Easy observation

Previously GravityTRAP™ ULA Plate

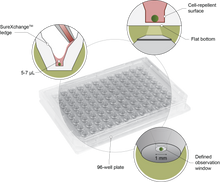

The Akura™ 96 Spheroid Microplate is designed for lossless spheroid/organoid formation and handling as well as reliable culturing and analysis.

- Unique SureXchange™ ledge engineered to prevent unintended spheroid/organoid aspiration

- Spheroid/organoid morphology and functionality are preserved in long-term culture by unique ULA coating

- Enhanced imaging speed and resolution through flat bottom well

- Improved spheroid/organoid formation with the Akura™ Tilting Stand by keeping the plate at 30 degrees during cell aggregation

Cat.-No.: CS-PB15

Features of Akura™ 96 Spheroid Microplate

The package includes 20 individually wrapped Akura™ 96 Spheroid Microplates, made of Cyclo olefin polymer, high-efficiency ULA coating, sterile, and includes a lid.

Architecture

- A Conical well design with SureXchange™ ledge protecting the spheroid/organoid from aspiration while leaving a minimal residual volume (5-7 µl).

- ANSI/SLAS standard format for full compatibility with automated liquid handling systems

- A leak-free and glue-free transparent polystyrene plate

Handling

- >90% medium removal without spheroid loss using manual and automated pipetting

- Ultra-low attachment surface with a stable cell-repellent coating

- Biologically inert, and non-degradable surface compatible with cell culture and in-plate post-culture processing steps such as cell lysis and fixation procedures

Imaging

- The flat bottom well minimizes optical aberration and ensures constant spheroid z-position

- Defined 1-mm quick-reference region of interest for increased imaging speed

Resources

At InSphero we are using our Akura™ Spheroid Microplates to produce and assay 3D microtissues for our partners in pharma and biotech. Our manuals and protocols contain valuable information and hands-on advice to make sure that these great plates work in your hands perfectly.

A detailed protocol for the production of spheroids in the Akura™ 96 Plate is provided in the product manual.

- Product Manual Akura™ 96 Spheroid Microplate

- Technical Specifications Akura™ 96 Spheroid Microplate

- Quick Start Guide Akura™ 96 Spheroid Microplate

-

[Technical Protocol] 3D Aggregation of Tumor Spheroids in the Akura™ 96 Spheroid Microplate

- Certificate of Compliance

FAQs of Akura™ 96 Spheroid Microplate

Q: What improvements did you make to the new Akura™ 96 Plate?

The improvements made to the Akura™ 96 Plate are:

Improved optical properties

• COP (Cyclo-Olefin Polymer, 92% transparency 400-800 nm) as plate material instead of Polystyrene.

• Thinner well bottom of 0.8 mm, before 1.3 mm.

• Reduced skirt height of 0.4 mm. High NA objectives may be used to image the outer wells of the plate.

Automation friendly

• Excellent planarity across the plate (below 80 μm) for reliable spheroid transfer and precise medium exchange.

Less evaporation

• Optimized distance (200 μm) between the customized low-evaporation lid and plate reduces evaporation in outer and edge wells

Q: Is the GravityTRAP ULA Plate identical to the Akura™ 96 Spheroid Microplate?

A: Yes, both plates are identical. We only changed the name as we recently expanded the InSphero microplate portfolio with additional products (e.g. Akura™ 384 Spheroid Microplate) and therefore, decided to put all plates under the new family brand name Akura™.

Q: Could you recommend a cell concentration for my cell suspension for the generating of spheroids/organoids?

A: For long-term growth profiling, we recommend starting with low cell numbers (250 – 500 cells per well of 70 μl). If the use of non-proliferating cells or rapid production of larger spheroids is required, start with higher numbers (from 2500+ cells per 70 μl).

Generally, we recommend trying different concentrations for defining your optimal range when using new cell types.

Q: What is the optimal volume per well in the Akura™ 96 Plate?

A: To achieve optimal volume per well, gently deliver 70 μl (pipetting speed < 10 μl/sec) of cell suspension into each well of the Akura™ 96 Plate by placing the pipette tips near, but not touching, the bottom of the wells.

Important - For spheroids with uniform size and cell composition it is essential to assure a homogeneous distribution of the cells by gently pipetting up and down prior to seeding into the Akura™ 96 Plate.

Q: Why do you recommend centrifuging the Akura™ 96 Plate after cell seeding?

A: We recommend briefly centrifuging the plate after cell seeding to remove any air bubbles and to force the cells to the bottom of the well in order to promote cell aggregation and spheroid formation.

For that, place the lid on the plate and spin it in a microtiter-plate centrifuge for 2 minutes at 250 RCF. Afterward, incubate the plate in a humidified CO2 incubator at 37 °C for 2-5 days.

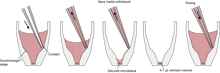

Q: How do I exchange the medium in the Akura™ 96 Plate without disturbing or losing the spheroids?

A: To prevent spheroid/organoid loss during the exchange of media, the SureXchange™ ledge at the inside wall of each well serves as an anchoring point for the pipette tip. Just place the tip at the ledge of the well, see figure below, and remove the medium at a low pipetting speed (>30 μl/sec). A minimal volume of ~ 5-7 μl will remain in the well.

Then, add 70 µl of the fresh medium by placing the pipette tip at the ledge, using a dispensing rate of <50 μl/sec.

Important - when using automated liquid handling devices, an off-center alignment of the vertical pipette tip will achieve the same effect.

Q: What is the best way to prevent evaporation in the outer wells of my plates?

A: Evaporation in the outer (perimeter) rows of wells is a phenomenon common to most low-volume culture platforms, and thus requires careful attention to maintaining proper humidity control. If not controlled, pronounced evaporation can result in the concentration or precipitation of media components (serum, salt) that can impact spheroid formation or health and can alter the effective concentration of a compound/additive in the medium over the course of a long-term experiment.

To provide maximum humidity control when using the Akura™ Plates, we recommend the following:

- Use an incubator with good humidity control (>95% of rel. humidity), and exercise best practices in maintaining and minimizing loss of humidity (e.g. minimize incubator door opening and closing).

- For culture in the Akura™ 96 Plate, at least 50-70 μl of the medium in each well is recommended and can be increased to a maximum of 80 μl if incubator humidity control is a persistent issue. Medium exchange frequency can also be increased to every other day or daily if conditions dictate.

- We recommend the use of the InSphero Incubox to reduce edge effects when performing long-term culture with the low-frequency medium exchange.

Selected Publications

Disclaimer - InSphero Akura™ 96 Spheroid Microplate was previously known as InSphero GravityTRAP™ ULA plate.

Disclaimer - InSphero’s plate technology is now under the name Akura™.

- Hofmann, Sarah, et al. "Patient-derived tumor spheroid cultures as a promising tool to assist personalized therapeutic decisions in breast cancer." bioRxiv (2021)

- Błyszczuk, Przemysław, et al. “Activated Cardiac Fibroblasts Control Contraction of Human Fibrotic Cardiac Microtissues by a -Adrenoreceptor-Dependent Mechanism.” Cells 9.5 (2020): 1270

- Mohan, Srinidi, et al. "Assessing the predictive response of a simple and sensitive blood-based biomarker between estrogen-negative solid tumors." Advances in Medical Sciences 65.2 (2020): 424-428

- Sánchez-González, Ismael, et al. "miR-149 suppresses breast cancer metastasis by blocking paracrine interactions with macrophages." Cancer research 80.6 (2020): 1330-1341

- Sun, Guoliang, et al. "Formation and optimization of three-dimensional organoids generated from urine-derived stem cells for renal function in vitro." Stem cell research & therapy 11.1 (2020): 1-12

- Wu, Cheng-Guang, et al. "In vitro cell culture of patient derived malignant pleural and peritoneal effusions for personalised drug screening." Journal of translational medicine 18.1 (2020): 1-9