Small Magnetic Loop Antenna Project - QRPBuilder.com

Small Magnetic Loop Antenna Project - QRPBuilder.com

Small Magnetic Loop Antenna Project - QRPBuilder.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

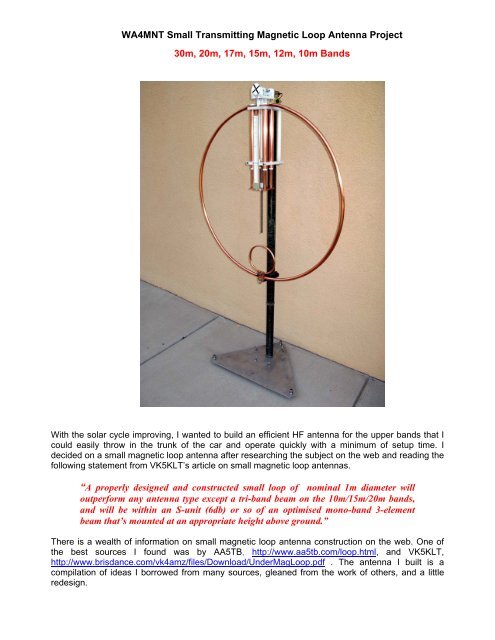

WA4MNT <strong>Small</strong> Transmitting <strong>Magnetic</strong> <strong>Loop</strong> <strong>Antenna</strong> <strong>Project</strong><br />

30m, 20m, 17m, 15m, 12m, 10m Bands<br />

With the solar cycle improving, I wanted to build an efficient HF antenna for the upper bands that I<br />

could easily throw in the trunk of the car and operate quickly with a minimum of setup time. I<br />

decided on a small magnetic loop antenna after researching the subject on the web and reading the<br />

following statement from VK5KLT’s article on small magnetic loop antennas.<br />

“A properly designed and constructed small loop of nominal 1m diameter will<br />

outperform any antenna type except a tri-band beam on the 10m/15m/20m bands,<br />

and will be within an S-unit (6db) or so of an optimised mono-band 3-element<br />

beam that’s mounted at an appropriate height above ground.”<br />

There is a wealth of information on small magnetic loop antenna construction on the web. One of<br />

the best sources I found was by AA5TB, http://www.aa5tb.<strong>com</strong>/loop.html, and VK5KLT,<br />

http://www.brisdance.<strong>com</strong>/vk4amz/files/Download/UnderMag<strong>Loop</strong>.pdf . The antenna I built is a<br />

<strong>com</strong>pilation of ideas I borrowed from many sources, gleaned from the work of others, and a little<br />

redesign.

This project resulted in a three foot diameter copper loop mounted on a small pedestal, with<br />

continuous coverage of 30m through 10m bands (10MHz-30MHz). I have been able to obtain an<br />

SWR of 1:1 - 1.2:1 over the entire range. Based on the advice of the most successful builders, I<br />

chose copper as the metal of choice and all joints are silver soldered to reduce the interconnection<br />

resistance. I chose to design my own trombone style capacitor (~10pF - ~110pF), and shielded<br />

Faraday <strong>Loop</strong> input. I used copper tubing, readily available low loss dielectric materials, PEX (cross<br />

linked polyethylene) tubing for the capacitor insulator, UHMW plastic (Polypropylene) for all other<br />

RF exposed parts, and non magnetic hardware for all mechanical fastening. My design was based<br />

on AA5TB’s on-line calculator, http://www.aa5tb.<strong>com</strong>/aa5tb_loop_v1.22a.xls, and my dielectric<br />

spacing exceeds a 2KW rating. I chose to mount my portable loop, a little less than one diameter,<br />

off the ground, from the bottom of the loop, with six radials, two loop diameters long, from the base.<br />

These antennas are high-Q resonant circuits. Many kilovolts can be present across<br />

the capacitor, and produce concentrated electro-magnetic radiation even at low<br />

power levels. For safety, maintain a minimum of 6 feet away from the antenna, while<br />

transmitting.<br />

I have access to milling and lathe equipment, so my exact approach may not be suitable for many<br />

amateurs; however many good designs are available using butterfly or vacuum capacitors and<br />

easier available tools. Even simpler monoband designs may be more appropriate. I incorporated a<br />

motor drive for remote tuning with a wired control cable. With the antenna bandwidth being so<br />

narrow, tuning for maximum receiver noise yields almost optimum SWR. I use no antenna tuner<br />

between the radio and antenna.<br />

I am not an antenna theoretician; my expertise is in mechanical design. I have attached all my<br />

detailed .pdf’s and defer to the <strong>com</strong>plete VK5KLT “An Overview of the Underestimated <strong>Magnetic</strong><br />

<strong>Loop</strong> HF <strong>Antenna</strong>” article at the end of this document for the theory of operation.<br />

Results using my MFJ-259B antenna analyzer:<br />

10m - 28.700 SWR 1.2 : 1 R=53, X=10<br />

28.200 SWR 1.1 : 1 R=46, X=8<br />

12m – 24.900 SWR 1.2 : 1 R=56, X=9<br />

15m – 21.300 SWR 1 : 1 R=47, x=0<br />

21.060 SWR 1 : 1 R=43, X=0<br />

17m – 18.150 SWR 1.2 : 1 R=43, X=7<br />

20m – 14.250 SWR 1.1 : 1 R=43, X=0<br />

14.060 SWR 1.1 : 1 R=44, X=0<br />

30m – 10.125 SWR 1.1 : 1 R=50, X=8<br />

<strong>Small</strong> magnetic loops typically have 5 dBi gain when used with two loop diameter length radials.<br />

They exhibit a vertically polarized signal at the horizon and horizontally polarized signal overhead.<br />

Thank you to all the amateurs that have shared their wisdom and made the information public on<br />

the internet to make this project a success.<br />

You may consider joining the Yahoo groups, <strong>Magnetic</strong><strong>Loop</strong><strong>Antenna</strong> or Mag<strong>Loop</strong><br />

Ken - WA4MNT<br />

www.qrpbuilder.<strong>com</strong><br />

E-mail – kloc@swiftwireless.<strong>com</strong>

Trombone style capacitor ~10pF – ~110pF<br />

Shielded Faraday input loop

Trombone capacitor gear drive<br />

Using a www.mpja.<strong>com</strong>, #16816MD, 24 vdc, 40 rpm gearmotor<br />

Frequency scale

Base with thumbscrews for 6’ radials, and surplus fiberglass mast section.<br />

Motor controller and cables 12v gel cell transceiver supply,<br />

with 12v to 24v switching supply<br />

DC-DC module, www.lightobject.<strong>com</strong><br />

for the gearmotor drive

Set up for operation<br />

<strong>Small</strong> enough to fit in the trunk of my Toyota Corolla

12v -24v switcher for gearmotor<br />

Motor controller, direction and speed<br />

www.mpja.<strong>com</strong>, #16816MD, 24v, 40 rpm gearmotor

Common Plastics Dissipation Factor Chart<br />

This will aid you in selecting suitable plastics for loop construction. Look for plastics with low dissipation<br />

factors. G10 /G11 glass epoxy board have a poor dissipation factor, 0.018, similar to PVC. UHMW<br />

(Polypropylene) is one tenth the cost of PTFE (Teflon).

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

SEE DETAIL B<br />

TROMBONE STYLE<br />

CAPACITOR<br />

`15pF - 80pF<br />

SEE DETAIL C<br />

SEE DETAIL D<br />

SEE DETAIL A<br />

1.825" O.D. FIBERGLASS MAST SECTION<br />

(MILITARY SURPLUS)<br />

ALUMINUM BASE PLATE<br />

2<br />

CAUTION !!!<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

6<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

ANG. # 0.5<br />

X # 0.25<br />

X.X # 0.1<br />

X.XX # 0.01<br />

X.XXX # 0.001<br />

6<br />

INITIAL RELEASE<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.048<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

THESE ANTENNAS ARE HIGH-Q RESONANT CIRCUITS.<br />

MANY KILOVOLTS CAN BE PRESENT ACROSS THE CAPACITOR,<br />

AND PRODUCE CONCENTRATED ELECTRO-MAGNETIC<br />

RADAITION EVEN AT LOW POWER LEVELS. FOR SAFETY,<br />

MAINTAIN A MINIMUM OF 6' AWAY FROM THE ANTENNA<br />

WHILE TRANSMITTING.<br />

NOTES:<br />

ALL COPPER ANTENNA ELEMENTS JOINED BY SILVER SOLDER<br />

ANY FASTENERS USED MUST BE 300 SERIES S.S.<br />

OPTIMUM HEIGHT IS TWO LOOP DIAMETERS ABOVE GROUND<br />

OPTIMUM RADIALS ARE ~2 LOOP DIAMETERS LONG<br />

FORMAT - B<br />

SHEET 1 OF 3<br />

WA4MNT 3' SMALL MAGNETIC<br />

LOOP ANTENNA 30m-10m<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

LOOP_ASSY<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

POINTER<br />

2<br />

1 3 4 7 8<br />

5<br />

2EA. STATOR SPACER<br />

DETAIL B<br />

SCALE 0.750<br />

2<br />

2 EA. MCM 7297K15 BEVEL GEARS & 2EA.<br />

.093 X .62 L. SS ROLL PINS<br />

ROTATION INDICATOR<br />

SHAFT<br />

SUPPORT<br />

2EA. ADJUSTMENT<br />

SPACER<br />

ANTENNA RING<br />

4EA. STATOR<br />

INSULATOR<br />

LOWER STATOR<br />

SUPPORT<br />

GEARSHAFT<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

6<br />

DETAIL A<br />

SCALE 0.750<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

ANG. # 0.5<br />

X # 0.25<br />

X.X # 0.1<br />

X.XX # 0.01<br />

X.XXX # 0.001<br />

6<br />

INITIAL RELEASE<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.048<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

FORMAT - B<br />

SHEET 2 OF 3<br />

WA4MNT 3' SMALL MAGNETIC<br />

LOOP ANTENNA 30m-10m<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

LOOP_ASSY<br />

DATE<br />

08/08/10<br />

WWW.MPJA.COM<br />

MOTOR #16816 MD<br />

12 VDC, 40 RPM<br />

BY<br />

KL<br />

MOTOR MOUNT<br />

ADJUSTMENT<br />

PLATE<br />

CONNECTOR<br />

BRACKET<br />

GEARSHAFT<br />

SPACER &<br />

SHORT<br />

GEARSHAFT<br />

UPPER STATOR<br />

SUPPORT<br />

2EA. STATOR<br />

ASSEMBLY<br />

2EA. STATOR<br />

SPACER<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

FARADAY LOOP<br />

ASSEMBLY<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

SO-239<br />

INPUT FLANGE<br />

2<br />

DETAIL D<br />

SCALE 0.500<br />

1 3 4 7 8<br />

5<br />

REV<br />

SCALE<br />

ROTOR ASSEMBLY<br />

SILVER SOLDER THE INPUT FLANGE TO<br />

THE ANTENNA RING ON THE BACKSIDE<br />

RING SUPPORT<br />

ANTENNA RING<br />

ECO<br />

6<br />

NUT<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

ANG. # 0.5<br />

X # 0.25<br />

X.X # 0.1<br />

X.XX # 0.01<br />

X.XXX # 0.001<br />

6<br />

INITIAL RELEASE<br />

SCALE<br />

SPACER<br />

LEADSCREW<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.048<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

DETAIL C<br />

SCALE 0.750<br />

FORMAT - B<br />

SHEET 3 OF 3<br />

WA4MNT 3' SMALL MAGNETIC<br />

LOOP ANTENNA 30m-10m<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

LOOP_ASSY<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

SILVER SOLDER AND DRILL PLUG TO ACCEPT<br />

RG-8 CENTER CONDUCTOR, SOLDER CENTER<br />

CONDUCTOR TO PLUG<br />

SILVER SOLDER BOTH PLATES TO SHELL<br />

2<br />

.50 REF.<br />

SCALE<br />

1.000<br />

INSIDE CONDUCTOR AND<br />

INSULATOR OF RG-8 COAX<br />

SLIP FIT INTO SHELL<br />

AT FINAL ASSEMBLY SOLDER RG-8 CENTER<br />

CONDUCTOR TO CENTER OF SO-239 CONNECTOR<br />

1.00 REF.<br />

.72<br />

1 3 4 7 8<br />

5<br />

REV<br />

FARADAY FLANGE<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

FARADAY SHELL<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.500<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

FARADAY_LOOP<br />

DATE<br />

08/07/10 08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

4EA. ROTOR - 1/2" RIGID COPPER TUBING<br />

PRESS IN<br />

4EA. ROTOR PLUG<br />

UPPER LEADSCREW WASHER<br />

& .25 SNAP RING<br />

2<br />

NUT W/4 EA. 6-32<br />

FH SCREWS<br />

ROTOR UNION<br />

LEADSCREW<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

LOWER LEADSCREW WASHER<br />

& 6-32 SCREW<br />

SILVER SOLDER 4 PLACES<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.250<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

SILVER SOLDER 4 PLACES<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/08/10<br />

ROTOR_ASSEMBLY<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

12.50<br />

5/8" I.D. "PEX" TUBING (ACE HDWR)<br />

SLIP FIT IN STATOR TUBE<br />

STATOR<br />

SILVER SOLDER 2 PLACES<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

2 PIECES REQUIRED<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.333<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

STATOR UNION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/08/10<br />

STATOR_ASSEMBLY<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

SCALE<br />

1.000<br />

1.00<br />

.50<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

6<br />

6.50<br />

NOTE: THIS DIAMETER IS DETERMINED BY EXPERIMENTATION<br />

AND IS APPROXIMATELY 1/5 LOOP DIAMETER<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.500<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - 3/8" O.D., 5/16" I.D. SOFT COPPER TUBING<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

FARADAY_SHELL<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.03<br />

2<br />

1.00<br />

.14<br />

.72<br />

.50<br />

.625<br />

.86<br />

4X R.06<br />

1 3 4 7 8<br />

5<br />

.50<br />

2X .125<br />

REV<br />

ECO<br />

.625<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 3.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - COPPER<br />

2 REQUIRED<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/08/10<br />

FARADAY_FLANGE<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.50<br />

6X .257<br />

2<br />

4.000<br />

3.750<br />

2.750<br />

1.750<br />

.750<br />

1 3 4 7 8<br />

5<br />

.250<br />

.000<br />

.76<br />

.000<br />

.500<br />

1.250<br />

2.000<br />

2.500<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

MATERIAL - UHMW<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT TITLE<br />

DO NOT SCALE<br />

SCALE: 1.000 FORMAT - B<br />

SHEET 1 OF 1<br />

3RD ANG<br />

PROJECT<br />

DESCRIPTION<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/08/10<br />

ADJUSTMENT_PLATE<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

1.500<br />

.750 .281<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - UHMW PLASTIC<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/08/10<br />

FORMAT - B DWG. NO.<br />

SHEET 1 OF 1ADJUSTMENT_SPACER<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

FLATTEN ~2.00<br />

BOTH SIDES<br />

1.50<br />

2<br />

5.50<br />

2X .281<br />

3.00<br />

SCALE<br />

0.200<br />

1 3 4 7 8<br />

5<br />

.625<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

36" TO CENTERLINE OF TUBING<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.059<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

SCALE<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

ANTENNA_RING<br />

DATE<br />

08/08/10<br />

0.100<br />

MATERIAL - 5/8" O.D. FLEXIBLE COPPER TUBING (ACE HWD)<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.06<br />

2<br />

2.50<br />

.25<br />

.75<br />

1.88<br />

1.50<br />

1.00<br />

2X .201<br />

1 3 4 7 8<br />

5<br />

.25<br />

.625<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - G10 GLASS EPOXY BOARD<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/08/10<br />

FORMAT - B DWG. NO.<br />

SHEET 1 OF 1CONNECTOR_BRACKET<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

.120<br />

.310<br />

1 3 4 7 8<br />

5<br />

REV<br />

.093<br />

ECO<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 8.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - BRASS OR COPPER<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

FARADAY_PLUG<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

.188<br />

1.500 .250<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - UHMW PLASTIC<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

GEAR_SPACER<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

.500<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

.250<br />

6-32 UNC - 2B TAP<br />

0.260 #36 DRILL ( 0.107 ) 0.320 -( 1<br />

) HOLE<br />

3.550<br />

.093<br />

.125<br />

.844<br />

1 3 4 7 8<br />

5<br />

.335<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

.197<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

6-32 UNC - 2B TAP 0.180<br />

#36 DRILL ( 0.107 ) 0.320 -( 1 ) HOLE<br />

MATERIAL - 316 SS<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

GEARSHAFT<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.02<br />

2<br />

1.375<br />

.439<br />

.75<br />

.094<br />

.02<br />

.250<br />

1 3 4 7 8<br />

5<br />

.200<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

MATERIAL - 300 SERIES S.S.<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 2.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/09/10<br />

GEARSHAFT_SHORT<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.125<br />

2<br />

1.875<br />

.265<br />

.359<br />

.718<br />

.25<br />

.359<br />

1.750<br />

1.00<br />

1 3 4 7 8<br />

5<br />

.718<br />

2.375<br />

.50<br />

REV<br />

.125<br />

.625<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - COPPER<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

INPUT_FLANGE<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

14.000<br />

8-32 UNC - 2B TAP 0.330<br />

#29 DRILL ( 0.136 ) 0.410 -( 1 ) HOLE<br />

1 3 4 7 8<br />

5<br />

.210<br />

.640<br />

6<br />

REV ECO<br />

DESCRIPTION<br />

DATE BY<br />

INITIAL RELEASE<br />

03/10/10 08/08/10 KL<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.666<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

SHEET 1 OF 1<br />

.030<br />

FORMAT - B<br />

1.685<br />

.76<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

DWG. NO.<br />

.250<br />

MATERIAL - 3/8-16 S.S. THREADED ROD<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

LEADSCREW<br />

.192<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.750<br />

2<br />

.250<br />

BOTH ENDS<br />

.375<br />

12.250<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

8-32 UNC - 2B TAP 0.330<br />

#29 DRILL ( 0.136 ) 0.410 -( 1 ) HOLE<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

MATERIAL - UHMW<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.333<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/08/10<br />

FORMAT - B DWG. NO.<br />

SHEET 1 OF 1LEADSCREW_COUPLER<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.060<br />

2<br />

.750 .136<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.005<br />

6<br />

INITIAL RELEASE<br />

MATERIAL - S.S.<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 3.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/09/10<br />

FORMAT - B DWG. NO.<br />

SHEET LEADSCREW_LOWER_WASHER<br />

1 OF 1<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

.060<br />

.75 .257<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.005<br />

6<br />

INITIAL RELEASE<br />

MATERIAL - S.S.<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 3.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/09/10<br />

FORMAT - B DWG. NO.<br />

SHEET LEADSCREW_UPPER_WASHER<br />

1 OF 1<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

3X .257<br />

R1.00<br />

1.850<br />

6.750<br />

2<br />

5.000<br />

2.750<br />

1.750<br />

4X .975<br />

.750<br />

.000<br />

4.500<br />

4.000<br />

3.750<br />

2.250<br />

.750<br />

.500<br />

.000<br />

1 3 4 7 8<br />

5<br />

.500<br />

.250<br />

.000<br />

REV<br />

4.250<br />

.250<br />

.000<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.500<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/08/10<br />

10-24 UNC - 2B TAP 0.360<br />

#25 DRILL ( 0.150 ) 0.450 -( 2 ) HOLE<br />

MATERIAL - UHMW PLASTIC<br />

FORMAT - B DWG. NO.<br />

SHEET 1 LOWER_STATOR_SUPPORT<br />

OF 1<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.50<br />

2<br />

.144<br />

.279 X 82°<br />

1.500<br />

1.093<br />

.220<br />

.000<br />

.500<br />

14-20 UNC - 2B TAP 0.460<br />

#10 DRILL ( 0.194 ) 0.580 -( 2 ) HOLE<br />

.000<br />

.844<br />

1.250<br />

1.500<br />

1.656<br />

1 3 4 7 8<br />

5<br />

.197<br />

2.500<br />

R.50<br />

REV<br />

.472<br />

ECO<br />

6<br />

.100<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - UHMW PLASTIC<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

MOTOR_MOUNT<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

1.500<br />

2<br />

.740<br />

.250<br />

1.440<br />

1 3 4 7 8<br />

5<br />

.750<br />

REV<br />

A<br />

ECO<br />

-<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

.750<br />

6<br />

INITIAL RELEASE<br />

4X .144 THRU, .279 X 82°<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

NUT<br />

NUT<br />

DATE<br />

04/24/10<br />

3/8-16 UNC - 2B TAP THRU<br />

5/16 DRILL ( 0.313 ) THRU -( 1 ) HOLE<br />

MATERIAL - UHMW PLASTIC<br />

BY<br />

KL<br />

REV<br />

A<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.196<br />

THRU, .385 X 82°<br />

2<br />

4.500<br />

4.500<br />

4.250<br />

3.005<br />

2.875<br />

1 3 4 7 8<br />

5<br />

1.625<br />

1.495<br />

.000<br />

.250<br />

.000<br />

REV<br />

ECO<br />

6<br />

.000<br />

.128<br />

.375<br />

.500<br />

.250<br />

.000<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

.070<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - CLEAR ACRYLIC<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

POINTER<br />

DATE<br />

BY<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2.000<br />

1.000<br />

.000<br />

2<br />

1 3 4 7 8<br />

5<br />

.000<br />

.250<br />

.500<br />

14-20 UNC - 2B TAP 0.460<br />

#10 DRILL ( 0.194 ) 0.580 -( 2 ) HOLE<br />

2<br />

3.000<br />

2.375<br />

1.500<br />

.625<br />

.000<br />

5.310<br />

2.630<br />

1 3 4 7 8<br />

5<br />

1.750<br />

REV<br />

.000<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

3RD ANG<br />

PROJECT<br />

1.850<br />

R1.00<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - UHMW PLASTIC<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

RING_SUPPORT<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

.06<br />

2.0 .140<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

PAINT WHITE, W/ BLACK CROSS<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - G10 GLASS EPOXY BOARD<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/08/10<br />

FORMAT - B DWG. NO.<br />

SHEET 1 OF 1ROTATION_INDICATOR<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

12.50<br />

SCALE<br />

0.750<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

6<br />

.625 O.D.<br />

.565 I.D.<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.333<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - 1/2" RIGID COPPER WATER PIPE<br />

4 REQUIRED<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

ROTOR<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

.660<br />

.750<br />

.558<br />

1.250<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

MATERIAL - UHMW<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 2.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

ROTOR_PLUG<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

4.000<br />

3.500<br />

2.375<br />

2.000<br />

1.625<br />

.500<br />

.000<br />

.000<br />

.500<br />

2<br />

1.125<br />

1.500<br />

1.875<br />

2.500<br />

3.000<br />

.620<br />

.750<br />

1 3 4 7 8<br />

5<br />

.250<br />

.125<br />

.000<br />

6-32 UNC - 2B TAP 0.260<br />

#36 DRILL ( 0.107 ) THRU -( 4 ) HOLE<br />

2.500<br />

1.500<br />

.000<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

ENG: WA4MNT TITLE<br />

DO NOT SCALE<br />

SCALE: 1.000 FORMAT - B<br />

SHEET 1 OF 1<br />

3RD ANG<br />

PROJECT<br />

DESCRIPTION<br />

6-32 UNC - 2B TAP 0.260<br />

#36 DRILL ( 0.107 ) 0.320 -( 2 ) HOLE<br />

MATERIAL - COPPER<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

ROTOR_UNION<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

.062<br />

.144<br />

1.500<br />

1.250<br />

.250<br />

.000<br />

1 3 4 7 8<br />

5<br />

14.250<br />

.125<br />

.000<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

MATERIAL - G10<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.500<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

SCALE<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

.250 SQ.<br />

.144<br />

1.500<br />

1.000<br />

1 3 4 7 8<br />

5<br />

REV<br />

.250<br />

ECO<br />

.125<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 2.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - ALUMINUM<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

SCALE_SPACER<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.02<br />

2<br />

1.375<br />

.439<br />

.75<br />

.094<br />

.02<br />

.250<br />

1 3 4 7 8<br />

5<br />

.200<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

MATERIAL - 300 SERIES S.S.<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 2.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/09/10<br />

GEARSHAFT_SHORT<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

SCALE<br />

12.00<br />

0.750<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

.962 .882<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.333<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - 3/4" COPPER REPAIR TUBING<br />

4 REQUIRED<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

STATOR<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

10.000<br />

1/4-20 UNC - 2B TAP 0.480<br />

#7 DRILL ( 0.201 ) 0.600 -( 1 ) HOLE<br />

.75<br />

1 3 4 7 8<br />

5<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.005<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.500<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

MATERIAL - UHMW PLASTIC<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

STATOR_SPACER<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

.25<br />

2<br />

1.500<br />

3.500<br />

2.000<br />

.960<br />

.257<br />

1 3 4 7 8<br />

5<br />

.750<br />

.750<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

MATERIAL - COPPER<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

STATOR_UNION<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

2<br />

1.500<br />

1 3 4 7 8<br />

5<br />

1.560<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 1.000<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

3/8-16 UNC - 2B TAP 0.750<br />

5/16 DRILL ( 0.313 ) 0.940 -( 1 ) HOLE<br />

MATERIAL - UHMW PLASTIC<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

TUBE_PIVOT<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

B<br />

A

D<br />

C<br />

B<br />

A<br />

2<br />

1 3 4 7 8<br />

5<br />

1.750<br />

1.000<br />

.25<br />

2<br />

.50<br />

.375<br />

R1.00<br />

2X .257<br />

6.750<br />

5.000<br />

4X .975<br />

2.750<br />

1.750<br />

.750<br />

1 3 4 7 8<br />

5<br />

.000<br />

10-24 UNC - 2B TAP 0.360<br />

#25 DRILL ( 0.150 ) 0.450 -( 2 ) HOLE<br />

.760<br />

4.500<br />

4.000<br />

3.750<br />

2.250<br />

.750<br />

.500<br />

.000<br />

REV<br />

ECO<br />

DIMENSIONS - INCHES<br />

UNLESS SPECIFIED<br />

TOLERANCES ARE:<br />

6<br />

ANG. ± 0.5 °<br />

X ± 0.25<br />

X.X ± 0.1<br />

X.XX ± 0.01<br />

X.XXX ± 0.001<br />

6<br />

INITIAL RELEASE<br />

ENG: WA4MNT<br />

DO NOT SCALE<br />

SCALE: 0.500<br />

3RD ANG<br />

PROJECT<br />

TITLE<br />

DESCRIPTION<br />

1/4-20 UNC - 2B TAP 0.480<br />

#7 DRILL ( 0.201 ) THRU -( 2 ) HOLE<br />

1/4-20 UNC - 2B TAP 0.480<br />

#7 DRILL ( 0.201 ) THRU -( 2 ) HOLE<br />

MATERIAL - UHMW PLASTIC<br />

THE INFORMATION CONTAINED IN THIS<br />

DOCUMENT IS THE PROPERTY OF<br />

BENT RIVER MACHINE AND SHALL NOT BE USED<br />

OR DISCLOSED OUTSIDE OF BENT RIVER MACHINE<br />

WITHOUT WRITTEN AUTHORIZATION<br />

FORMAT - B<br />

SHEET 1 OF 1<br />

DWG. NO.<br />

WA4MNT<br />

P.O. BOX 956<br />

CLARKDALE, AZ 86324<br />

928-639-3481 (VOICE)<br />

WWW.QRPBUILDER.COM<br />

DATE<br />

08/08/10<br />

BY<br />

KL<br />

REV<br />

D<br />

C<br />

UPPER_STATOR_SUPPORT<br />

B<br />

A

An Overview of the Underestimated <strong>Magnetic</strong> <strong>Loop</strong> HF <strong>Antenna</strong><br />

It seems one of the best kept secrets in the amateur radio <strong>com</strong>munity is how well a small<br />

diminutive magnetic loop antenna can really perform in practice <strong>com</strong>pared with large<br />

traditional HF antennas. The objective of this article is to disseminate some practical<br />

information about successful homebrew loop construction and to enumerate the loop’s key<br />

distinguishing characteristics and unique features. A magnetic loop antenna can very<br />

conveniently be ac<strong>com</strong>modated on a table top, hidden in an attic / roof loft, an outdoor<br />

porch, patio balcony of a high-rise apartment, rooftop, or any other space constrained site.<br />

A small but efficacious HF antenna for restricted space sites is the highly sort after Holy<br />

Grail of many an amateur radio enthusiast. This quest and interest is particularly strong<br />

from amateurs having to face the prospect of giving up their much loved hobby as they<br />

move from suburban residential lots into smaller restricted space retirement villages and<br />

other <strong>com</strong>munities that have strict rules against erecting elevated antenna structures. In<br />

spite of these imposed restrictions amateurs do have a practical and viable alternative<br />

means to actively continue the hobby using a covert in-door or portable outdoor and<br />

sympathetically placed small magnetic loop. This paper discusses how such diminutive<br />

antennas can provide an entirely workable <strong>com</strong>promise that enable keen amateurs to keep<br />

operating their HF station without any need for their previous tall towers and favourite<br />

beam antennas or unwieldy G5RV or long wire. The practical difference in station signal<br />

strength at worst will be only an S-point or two.<br />

Anyone making a cursory investigation into the subject of magnetic loop antennas using<br />

the Google internet search engine will readily find an overwhelming and perplexing<br />

abundance of material. This article will assist readers in making sense of the wide diversity<br />

of often times conflicting information with a view to facilitate the assimilation of the<br />

important essence of practical knowledge required to make an electrically-small loop work<br />

to its full potential and yield very good on-air performance.<br />

A few facts:<br />

A properly designed and constructed small loop of nominal 1m diameter will outperform<br />

any antenna type except a tri-band beam on the 10m/15m/20m bands, and will be within an<br />

S-point (6dB) or so of an optimised mono-band 3-element beam that’s mounted at an<br />

appropriate height above ground.<br />

<strong>Magnetic</strong> loops really <strong>com</strong>e into their own on the higher HF bands from say 40m through<br />

to 10m; oftentimes with absolutely stunning performance rivalling the best conventional<br />

antennas. Easily field deployable and fixed site tuned loops have been the routine antenna<br />

of choice for many years in professional defence, military, diplomatic, and shipboard HF<br />

<strong>com</strong>munication links where robust and reliable general coverage radio <strong>com</strong>munication is<br />

deemed mandatory. On 80m and 160m top-band the performance of a small loop antenna<br />

generally exceeds that achievable from a horizontal dipole, particularly one deployed at<br />

sub-optimal height above ground. This is a <strong>com</strong>mon site limitation for any HF antenna.<br />

So where’s the catch; if the small loop is such a good antenna why doesn’t everyone have<br />

one and dispense with their tall towers? The laws of nature and electromagnetics cannot be<br />

violated and the only unavoidable price one pays for operating with an electrically-small<br />

antenna is narrow bandwidth. Narrow instantaneous bandwidth rather than poor efficiency<br />

is the fundamental limiting factor trade-off with small loops.<br />

1

Any small antenna will be narrow band and require tuning to the chosen operating<br />

frequency within a given band. Users of magnetic loops must be content with bandwidths<br />

of say 10 or 20 kHz at 7 MHz or a little more than 0.2%. They are content as long as the<br />

antenna can be easily tuned to cover the frequencies that they wish to use. For a remotely<br />

sited or rooftop mounted antenna implementing this tuning requires just a modicum of that<br />

ingenuity and improvisation radio hams are renowned for.<br />

A small transmitting loop (STL) antenna is defined as having a circumference of more than<br />

one-eighth wavelength but somewhat less than one-third wavelength which results in an<br />

approximately uniform current distribution throughout the loop and the structure behaves<br />

as a lumped inductance. The figure-8 doughnut shaped radiation pattern is in the plane of<br />

the loop with nulls at right angles to the plane of the loop. The loop self-inductance can be<br />

resonated with a capacitance to form a high-Q parallel tuned circuit. The attainment of a<br />

high-Q tells us that the loop antenna is not lossy and inefficient. When power is applied to<br />

the loop at its resonant frequency all of that power will be radiated except that portion<br />

absorbed in the lumped I 2 R conductor and capacitor losses manifesting as wasteful heat.<br />

With proper design these series equivalent circuit losses can be made negligible or at least<br />

sufficiently small <strong>com</strong>pared to the loop’s radiation resistance that resultantly high intrinsic<br />

radiation efficiency and good antenna performance can be achieved.<br />

Current through the loop’s radiation resistance results in RF power being converted to<br />

electromagnetic radiation. However, since the small loop’s radiation resistance is very<br />

small <strong>com</strong>pared to that of a full sized resonant ½ λ dipole, getting this favourable ratio of<br />

loss to radiation resistance is the only “tricky” and challenging part of practical loop design<br />

and homebrew construction. Through utilizing a split-stator or a butterfly style air variable<br />

capacitor construction or preferably a vacuum variable capacitor, low loss can be achieved<br />

in the tuning capacitor. Conductor loss can then be controlled by optimal choice of the<br />

diameter of copper tubing used to form the loop element and paying very careful attention<br />

to low ohmic interconnections to the capacitor such as welded or silver soldered joints, etc.<br />

With 100 Watts of Tx drive power there are many tens of Amperes of RF circulating<br />

current and Volt-Amps-Reactive (VAR) energy flowing in the loop conductor and tuning<br />

capacitor.<br />

In the case of an air variable, capacitor losses are further minimised by welding the rotor<br />

and stator plates to the stacked spacers to eliminate any residual cumulative contact<br />

resistance. When connected across the loop terminals the butterfly construction technique<br />

inherently eliminates any lossy rotating contacts in the RF current path. The configuration<br />

permits one to use the rotor to perform the variable coupling between the two split stator<br />

sections and thus circumvent the need for any lossy wiper contacts to carry the substantial<br />

RF current. Since the fixed stator plate sections are effectively in series, one also doubles<br />

the RF breakdown voltage rating of the <strong>com</strong>posite capacitor. In view of the fact the loop<br />

antenna is a high-Q resonant circuit, many kilovolts of RF voltage can be present across<br />

the tuning capacitor and appropriate safety precautions must be taken. <strong>Small</strong> transmitting<br />

loop antennas capable of handling a full 400 Watts PEP or greater are readily achievable<br />

when appropriate construction and tuning <strong>com</strong>ponents are selected.<br />

Feeding and matching:<br />

Although loop antennas have deceptively simple appearance, they are <strong>com</strong>plex structures<br />

with radiation patterns and polarisation characteristics dependent on whether they’re fed in<br />

a balanced or unbalanced fashion. The method of feeding and matching the loop resonator,<br />

2

ground plane configuration, as well as the geometric form factor and physical proportions<br />

of the loop element itself are all fertile ground for experimentation. Various matching<br />

methods include series capacitor, transformer coupled subsidiary shielded-Faraday loop,<br />

and gamma-match, etc; each with their respective merits.<br />

The choice really boils down to personal preference as both the gamma and Faraday feed<br />

techniques work well. However, the Faraday shielded auxiliary loop located at the bottom<br />

central symmetry plane yields better loop electrical symmetry and balance that can in turn<br />

provide sometimes beneficial deeper front-to-side ratio and pattern nulls. In addition to<br />

imparting slight pattern asymmetry the Gamma match method can also result in some<br />

deleterious <strong>com</strong>mon-mode current flow on the outer braid of the feed coax that might need<br />

choking-off and isolating with ferrite decoupling balun to prevent spurious feeder radiation<br />

and extraneous noise pick-up on Rx. Much also depends on the site installation set up in<br />

respect of conductive objects in the loop’s near field that can disturb symmetry.<br />

With the elegantly simple transformer-coupled Faraday loop feed method the 50Ω signal<br />

source merely feeds the auxiliary loop; there’s no other coupling / matching <strong>com</strong>ponents<br />

required as there are no reflected reactive <strong>com</strong>ponents to deal with (the main loop appears<br />

purely resistive at resonance with just the core Rrad and Rloss <strong>com</strong>ponents in series).<br />

The impedance seen looking into the auxiliary feed loop is determined solely by its<br />

diameter with respect to the primary tuned resonator loop. A loop diameter ratio of 5:1<br />

typically yields a perfect match over a 10:1 or greater frequency range of main loop tuning.<br />

Simple transformer action occurs between the primary loop and the feed loop coupled<br />

circuit due to the highly reactive field near the resonant primary loop which serves to<br />

greatly concentrate magnetic flux lines which cut the small untuned feed loop. The degree<br />

of magnetic flux concentration is a function of the Q of the tuned primary which varies<br />

with frequency, i.e. the highest Q occurring at the lowest frequency of operation and the<br />

lowest Q exhibited at the highest frequency. This variation in Q results from the variation<br />

in the sum of the loss resistance and the <strong>com</strong>plex mode radiation resistances of the primary<br />

radiator loop as a function of frequency. The effective feed impedance of the secondary<br />

loop is controlled by its diameter / ratio of area and by the number of flux lines cutting it;<br />

thus the impedance seen looking into the secondary loop will be essentially independent of<br />

frequency. One can intuitively see this because when the feed loop is extremely small in<br />

relation to a wavelength at the lowest frequency of operation, the number of magnetic flux<br />

lines cutting it is large because of the very high Q, whereas when the feed loop be<strong>com</strong>es a<br />

larger fraction of a wavelength as the frequency of resonance is increased, the<br />

concentration of flux lines is reduced due to the lower Q.<br />

If one seeks mode purity and figure-8 pattern symmetry with deep side nulls, the fully<br />

balanced Faraday transformer coupled subsidiary broadband impedance matching loop<br />

with its 5:1 diameter ratio would be the preferred choice of feed structure.<br />

<strong>Loop</strong> balance is also important for rejecting local electric E-field conveyed noise; whereas<br />

the small loop is predominantly H-field responsive, any electrical imbalance results in<br />

<strong>com</strong>mon-mode currents on the feeder that will impart deleterious E-field sensitivity which<br />

may contribute to additional local noise pickup. That inherent loop imbalance and<br />

asymmetry is one of the slight trade-offs associated with a Gamma feed <strong>com</strong>pared to an<br />

auxiliary Faraday loop transformer feed. This aberration is not an issue with Tx mode of<br />

course.<br />

3

<strong>Loop</strong> radiation characteristics:<br />

<strong>Small</strong> loop antennas have at least two simultaneously excited radiation modes; a magnetic<br />

and an electric folded dipole mode. When the ratio proportions of loop mode and dipole<br />

mode radiation are juggled to achieve equal strengths some radiation pattern asymmetry<br />

results and a useful degree of uni-directionality can be achieved with a typical front to back<br />

ratio of about 6dB or so.<br />

The small loop with its doughnut shaped pattern exhibits a typical gain of 1.5 dBi over<br />

average ground and a gain of 5 dBi when deployed with either short radials (the length of<br />

each radial need only be twice the loop diameter) or mounted over a conductive ground<br />

plane surface. By <strong>com</strong>parison a large ½ λ horizontal dipole mounted ¼ λ above average<br />

ground has a gain of 5.12 dBi and a ¼ λ Vertical with 120 radials each ¼ λ long has a gain<br />

of 2 dBi over average ground. The front to side ratio of a well balanced loop is typically<br />