Segmental Retaining Wall Systems - Thewebconsole.com

Segmental Retaining Wall Systems - Thewebconsole.com

Segmental Retaining Wall Systems - Thewebconsole.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

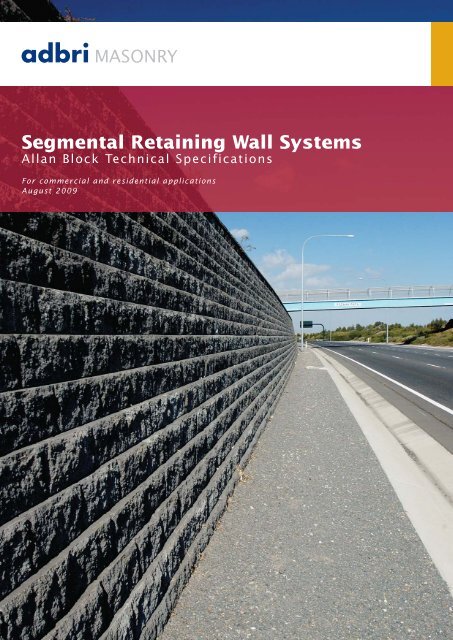

<strong>Segmental</strong> <strong>Retaining</strong> <strong>Wall</strong> <strong>Systems</strong>Allan Block Technical SpecificationsFor <strong>com</strong>mercial and residential applicationsAugust 2009

IntroductionThe designs provided in this brochure are forgravity retaining wall systems designed inaccordance with the requirements of AS4678“Earth-retaining Structures”.In some instances, designs have been providedutilising no fines concrete behind the retainingwall units to provide additional stability forthe wall system, and increase the maximumpermissable design height.The designs provided with no fines concreteare done within the limits of economy.Excessive amounts of no fines concrete areexpensive, and for our larger retaining wallsystems it will be<strong>com</strong>e more cost effective toutilise a Geogrid reinforced wall system.For information on Geogrid reinforced walls,please refer to page 35.This brochure has been prepared by Adbri Masonry. All designs in this brochurehave been checked and approved by Arlene Nardone, RPEQ 7777 and Wayne HoltCPEng, NPER, RPEQ 5510.Disclaimer:It is the responsibility of the customer to ensure that all assumed properties(Note 2 of Technical Parameters) are achieved on site, and that all retaining wallsare installed as per requirements of designs and cross sectional details. AdbriMasonry accepts no liability for any walls outside the scope of designs includedin this brochure, or for installation of the products contained within.

1.0 Technical Parameters031. Designed in accordance with the followingstandards unless noted otherwise.AS4678:2002 – Earth retaining structuresAS1170.1:2002 – Loading CodeAS3700:2001 – Masonry CodeAS2870:1996 – Residential Slabs andFootingsConcreteAggregate– Grade N20, min. 80mmslump, 20mm max.aggregate.– 12 - 20mm max.No Fines Concrete – 20mm max. aggregate,6:1 Dry mix.2. The soil types and properties assumed in design are:MaterialInsitu material 19Gravel backfill 19Concrete 24Internal FrictionAngle (ø)Unit Weight kN/m 3 30CGM 18 37 0Foundationreplacement zones37N/ACohesive Strength kPa19 42 0No fines concrete (NFC) 19 N/A 0000Notes:Where depth of aggregate exceeds 300mm, infill material is deemed to be the material being retained.If natural material on site does not meet or exceed a 30º internal friction angle, you must use a foundation replacement zone and a H/2aggregate infill material. NFC designs will not be applicable and further engineering advice will be required. A geotechical engineer willbe able to assist you in evaluating your in-situ material.No design consideration has been given for rock excavation. With the assumed founding soil properties, the allowable bearing capacityunder a normal load has been taken at 100kPa.The properties of the materials should be checked by a geotechnical engineer if doubt exists. Design has been based on assumed averageconditions for a gravity retaining wall and is considered applicable to soils where the site is classified as S, M, H or E with “ys” less than 70mm,where the wall is founded on natural undisturbed material. The infill of the wall must be <strong>com</strong>pacted to ensure against rotation of the wall backwards.3. These details are not applicable to the following designs and require the specific design input of a registered professional engineer:(a) <strong>Wall</strong> heights greater than shown in the tables(b) Surface slopes greater than 1V:4H at top of wall.(c) Site ground slopes greater than 1V:4H at toe of wall.(d) Retained material properties differing from those assumed in the design.(e) <strong>Wall</strong>s founded on fill.(f) Rock encountered in excavation of area for infill material.(g) Site classified as “E” Ys greater than 70mm or “P”. For “E” sites where Ys exceeds 70mm a geotechnical engineer should be engaged.For “P” sites, you must ensure that a safe bearing capacity of 100kPa is achieved, and satisfy yourself that no long term settlement will occur.(h) Site has major drainage or seepage problems.(i) Lack of global stability. Global stability should be checked by a qualified geotechnical engineer.(j) The founding material has a bearing capacity less than 100kPa.(k) Where the possibility of failure of the toe of the wall exists due to location of building or service pipe trenches in front of thewall prior to or after construction of the retaining wall.(l) Where fences are detailed to be installed at the top of the wall which do not <strong>com</strong>ply with the fence post installation detailincluded in this brochure.(m) Where replacement material zones are not able to be installed as detailed in the design tables.4. The conditions below must be met for residential walls denoted by * as shown in design tables for residential walls to 1200mm max. height:1. All retaining walls are designed to CMAA document MA53 (<strong>Segmental</strong> Concrete Gravity <strong>Retaining</strong> <strong>Wall</strong>s Design and Construction Guide).2. All retaining walls shall <strong>com</strong>ply with AS4678 Structure Classification A.3. These tables are only applicable to retaining walls that incorporate a low permeability surface membrane and drainage systemsuch that there can be no ingress of any water into the soil behind the retaining wall.4. Stuctures that do not incorporate a low permeability surface membrane and drainage system such that there can be no ingressof any water into the soil behind the retaining wall are deemed to be outside the scope of this brochure.5. These tables are applicable to cuts in insitu soils. The tables are not applicable to cohesive fill.6. All retaining walls are designed for a maximum surcharge load of 2.5 kPa. If surcharge loads greater than 2.5 kPa are expected,these designs will not be appropriate.7. The footing for Meadow Stone consists of at least 5% cement-stabilised crushed rock with dimensions as detailed. Before the bottomcourse is positioned, the footing should be moistened to ensure bond between block and footing.These walls have been designed in accordance with Rankine Bell Methodology.5. The segmental retaining wall units in this brochure, with the exception of the Landmark system, have keys which are utilised for locatingpurposes only and are therefore not subject to the dimensional tolerances outlined in table 2.3 of AS4455.3:2008 “<strong>Segmental</strong> <strong>Retaining</strong><strong>Wall</strong> Units”. The Landmark system has been independently tested to ensure integrity of the structural key for the purpose of constructinggeogrid reinforced walls up to 20m in height.

2.0 General Notes041. <strong>Wall</strong> construction to be executed in accordance with the requirements of this brochure.2. The walls have been designed for the following surcharge loads :• 1kPa (for garden walls) to 800mm maximum height.• 2.5kPa for walls between 800mm and 1500mm in height.• 5 kPa for walls exceeding 1500mm in height.• No Dead Loads have been allowed for.• Cohesion c=4kPa for residential walls denoted by * :Where there are any variations to the materials, soil conditions, loadings, drainage, geometry of the site or retaining wall,a registered engineer should be engaged to design the wall.3. Where a fence is required at the top of the wall, the fence shall be installed in accordance with the detail in this manual.4. Structures such as building footings, swimming pools, other retaining walls, storage facilities or solid panel fencing and loads suchas from motor vehicle access must be kept clear such that the load is not placed within a line projected behind the wall from thefounding level at 1V:1.5H. Where structures or driveways do intrude within this line a registered professional engineer should beengaged to design the wall.5. Precautions must be taken where other building work or service trenches are excavated around the retaining wall, as it may be necessaryto use bridging foundations or other alternatives.6. In all wall units with voids, stability depends on the blocks remaining filled, with Windsor, Diamond, Landmark, all the AB unitsand Hampton Stone <strong>Retaining</strong> <strong>Wall</strong> blocks, the first course should be installed with the shear key down and placed to give firm evenbearings on the leveling pad, level front to back and side to side.7. The base of the leveling pad excavation should be firm, dry and free of loose material. Any disturbed ground at the base of thetrench should be <strong>com</strong>pacted prior to footing construction. All retained material must be <strong>com</strong>pacted by firm tamping using appropriate<strong>com</strong>paction equipment. Materials in front of the wall should be founding soil or equivalent and thoroughly <strong>com</strong>pacted immediatelyafter the wall is out of the ground.8. If the insitu material is equal to or exceeds the properties of the proposed infill material, then the insitu material shall be substitutedfor the infill material.9. Precautions should be taken if cutting back the existing bank to ensure such excavation does not destabilize the footing of another structure.10. <strong>Wall</strong>s may be constructed to greater heights in specific applications with special engineering design.11. Check with your local council whether building approval is required.12. It is re<strong>com</strong>mended that the top course is epoxied to the next course with waterproof construction epoxy as a precautionary measure.Adbri Masonry re<strong>com</strong>mends the use of the AV Syntec product AV515 or equivalent.13. Where these walls impose loads on other structures those other structures must be checked for strength and stability.14. Where a foundation replacement zone is detailed, this will denote the removal of natural material where detailed, and replacementwith CBR45 road base <strong>com</strong>pacted to 98% Standard Relative Dry Density (RDD).15. External interface friction angle is calculated as being equal to 2/3 ø where ø is the internal friction angle.16. Subsoil drains should be flushed at regular intervals to ensure continuous proper functioning of the retaining wall drainage system.17. Subsoil drains shall have outlet points at maximum 20m centres for dry application and maximum 5m centres for wet application.

3.0 Typical Detailsfor <strong>Segmental</strong> <strong>Retaining</strong> <strong>Wall</strong>s053.1 Drainage of Backfill(Detailed using Terrace units, but information is applicable to all product types)Before a segmental retaining wall is constructed consideration must be given to the need for and the means of drainage.Each individual site needs to be assessed and measures taken appropriate to the source and the volume of waterexpected behind the wall. The following general guidelines will assist in deciding on the type of drainage required,but are not intended to replace professional advice.In the event of heavy rain before planting is established, the top of the wall should be covered with plastic sheets ortarpaulins to prevent the soil being scoured out.A. Only direct rainon backfillLow permeability layerA.Where there is a small width ofbackfill, it is sufficient that thebackfill be <strong>com</strong>posed of drainageaggregate to permit drainage throughthe wall. Where there is a large widthof backfill, it must be sealed with alow permeability layer eg. clay layer,concrete slab etc, to preventthe backfill be<strong>com</strong>ing saturated.B. Sub-soil seepageentering backfillLow permeability layerB.In this case it will be necessary tointercept the water and direct it away.This can usually be achieved byproviding a layer of gravel behind thewall to collect the water, and anagricultural pipe at the base to carrythe water away.C. Areas of heavy rainfallor surface run-off waterLow permeability layerC.In this case the surface must be sealedwith a low permeability layer to preventsaturation of the backfill and asurface drain provided to direct wateraway in order to prevent scouring.Diagrams not to scale

073.3 Typical Fence Post DetailDetail A:*------------------------Grout fence posts intopvc pipes installed duringwall constructionDetail A:*11.5No structural loadswithin this line11.5No structural loadswithin this lineInstall pvc pipes of required diameterto underside of structural load lineat required centresIn Detail A:*Use galvanised steel plates and cast in place bolts to connect to 600 diameter piers at 3m ctrs reinforced with 4 12mm bars and 8mm ligatures at 400 ctrs.3.4 Typical No Fines Concrete Installation DetailsInfill deptha)Low permeability layerb)Place no fines concrete in single blocklifts of 200mm or less (depending uponheight of block). Ensure no fines ismanipulated into V shaped void betweenunits to ensure adequate bond betweenblock and concrete mass.tIf units are cored through, the no finesconcrete must also <strong>com</strong>pletely fill thecored section of the block.c)When using no fines concrete, ensure bondis achieved between wall units and nofines concrete. Ensure that no fines concreteis placed in voids between all units.Compacted roadbasefoundation replacement zoneIf any of the blocks have an internal core, thisshould be filled with no fines concrete as well.Throat width (t) of no fines concrete shallnever be less than 50mm. Blocks shall bemodified by contractors where necessaryto ac<strong>com</strong>modate this.Diagrams not to scale

09AB Aussie Typical <strong>Wall</strong> Section1:4 max slopeInfill DepthAB Capper(Short)Level SlopeLow permeability top soil layerAB Aussie1No structural loadswithin this line"H" Design height9.5Infill Material*1.51*Refer to page 9 when using No Finesconcrete infill materiale100mm Subsoil drain socked fall to dischargemaximum 20m centres13020mPa Concrete leveling pad130Additional extent of foundation replacement zonerequired when NFC infill material is used (refer tosection 3.4)450Foundation replacement zone <strong>com</strong>pacted roadbase 98% min RDD if requiredAB Aussie Vertical Typical <strong>Wall</strong> Section1:4 max slopeInfill DepthAB Capper(Short)Level SlopeLow permeability top soil layerAB Aussie Vertical1No structural loadswithin this line"H" Design height40Infill Material*1.51*Refer to page 9 when using No Finesconcrete infill materiale100mm Subsoil drain socked fall to dischargemaximum 20m centres13020mPa Concrete leveling pad130Additional extent of foundation replacement zonerequired when NFC infill material is used (refer tosection 3.4)450Foundation replacement zone <strong>com</strong>pacted roadbase 98% min RDD if requiredDiagrams not to scale

10AB Aussie <strong>Retaining</strong> <strong>Wall</strong> Design HeightsResidential <strong>Retaining</strong> <strong>Wall</strong>s(Including residential subdivisions)Design Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level2400 1:4 maximum2200 1:4 maximum2000 1:4 maximum5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone1 Replacement Zone1 Natural Material1 Natural Material5 Replacement Zone5 Replacement Zone5 Replacement ZoneNFC 800NFC 750NFC 700NFC 600NFC 550NFC 500NFC 350NFC 300NFC 300Aggregate 300Aggregate 300Aggregate 300NFC 1000NFC 900NFC 8501800 1:4 maximum 5 Replacement Zone NFC 7501600 1:4 maximum 5 Replacement Zone NFC 6501400 1:4 maximum 2.5 Replacement Zone NFC 4501200 1:4 maximum 2.5 Replacement Zone NFC 3501000 1:4 maximum 2.5 Replacement Zone NFC 300800 1:4 maximum 1 Replacement Zone Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

11AB Aussie <strong>Retaining</strong> <strong>Wall</strong> Design HeightsCommercial <strong>Retaining</strong> <strong>Wall</strong>sDesign Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone1 Replacement Zone1 Natural Material1 Natural MaterialNFC 800NFC 750NFC 700NFC 600NFC 550NFC 500NFC 350NFC 300NFC 300Aggregate 300Aggregate 300Aggregate 3002400 1:4 maximum 5 Replacement Zone NFC 10002200 1:4 maximum 5 Replacement Zone NFC 9002000 1:4 maximum 5 Replacement Zone NFC 8501800 1:4 maximum 5 Replacement Zone NFC 7501600 1:4 maximum 5 Replacement Zone NFC 6501400 1:4 maximum 2.5 Replacement Zone NFC 4501200 1:4 maximum 2.5 Replacement Zone NFC 3501000 1:4 maximum 2.5 Replacement Zone NFC 300800 1:4 maximum 1 Replacement Zone Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

12AB Aussie Vertical <strong>Retaining</strong> <strong>Wall</strong> Design HeightsResidential <strong>Retaining</strong> <strong>Wall</strong>s(Including residential subdivisions)Design Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level2400 1:4 maximum2200 1:4 maximum2000 1:4 maximum5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone1 Replacement Zone1 Natural Material1 Natural Material5 Replacement Zone5 Replacement Zone5 Replacement ZoneNFC 950NFC 900NFC 800NFC 750NFC 650NFC 550NFC 400NFC 300NFC 300Aggregate 400Aggregate 300Aggregate 300NFC 1100NFC 1000NFC 9501800 1:4 maximum 5 Replacement Zone NFC 8501600 1:4 maximum 5 Replacement Zone NFC 7501400 1:4 maximum 2.5 Replacement Zone NFC 5501200 1:4 maximum 2.5 Replacement Zone NFC 4501000 1:4 maximum 2.5 Replacement Zone NFC 350800 1:4 maximum 1 Replacement Zone Aggregate 400600 1:4 maximum 1 Replacement Zone Aggregate 300400 1:4 maximum 1 Replacement Zone Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

13AB Aussie Vertical <strong>Retaining</strong> <strong>Wall</strong> Design HeightsCommercial <strong>Retaining</strong> <strong>Wall</strong>sDesign Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone1 Replacement Zone1 Natural Material1 Natural MaterialNFC 950NFC 900NFC 800NFC 750NFC 650NFC 550NFC 400NFC 300NFC 300Aggregate 400Aggregate 300Aggregate 3002400 1:4 maximum 5 Replacement Zone NFC 11002200 1:4 maximum 5 Replacement Zone NFC 10002000 1:4 maximum 5 Replacement Zone NFC 9501800 1:4 maximum 5 Replacement Zone NFC 8501600 1:4 maximum 5 Replacement Zone NFC 7501400 1:4 maximum 2.5 Replacement Zone NFC 5501200 1:4 maximum 2.5 Replacement Zone NFC 4501000 1:4 maximum 2.5 Replacement Zone NFC 350800 1:4 maximum 1 Replacement Zone Aggregate 400600 1:4 maximum 1 Replacement Zone Aggregate 300400 1:4 maximum 1 Replacement Zone Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

144.13 AB Classic(Allan Block) Classic200No. Per m 2 of <strong>Wall</strong> 11.5435305Approx. WeightSetback31.25kg1:9.5 (6˚)Allan Block Curves DetailRemove wingsfor outside radiusAll cores and voids between units to be filledwith infill material at all timesAllan Block Corners DetailRight AnglesFirst CourseRemovelip to allownext courseSecond CourseOutside angles other than 90˚Modify adjacentunits as requiredto maintain bondAlternate Leftand Right handcorner unitsCut units to achieve desiredangle and glue in placeModify adjacentunits as requiredto maintain bondDiagrams not to scale

15AB Classic Typical <strong>Wall</strong> Section1:4 max slopeInfill DepthAB CapperLevel SlopeLow permeability top soil layerAB Classic1No structural loadswithin this line"H" Design height9.5Infill Material*1.51*Refer to page 9 when using No Finesconcrete infill materiale100mm Subsoil drain socked fall to dischargemaximum 20m centres15020mPa Concrete leveling pad150Additional extent of foundation replacement zonerequired when NFC infill material is used (refer tosection 3.4)600Foundation replacement zone <strong>com</strong>pacted roadbase 98% min RDD if requiredDiagrams not to scale

16AB Classic <strong>Retaining</strong> <strong>Wall</strong> Design HeightsResidential <strong>Retaining</strong> <strong>Wall</strong>s(Including residential subdivisions)Design Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level2400 1:4 maximum2200 1:4 maximum2000 1:4 maximum5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Natural Material1 Natural Material1 Natural Material1 Natural Material5 Replacement Zone5 Replacement Zone5 Replacement ZoneNFC 750NFC 700NFC 600NFC 550NFC 450NFC 400NFC 300NFC 300Aggregate 300Aggregate 300Aggregate 300Aggregate 300NFC 900NFC 850NFC 7501800 1:4 maximum 5 Replacement Zone NFC 7001600 1:4 maximum 5 Replacement Zone NFC 6001400 1:4 maximum 2.5 Replacement Zone NFC 4001200 1:4 maximum 2.5 Replacement Zone NFC 3001000 1:4 maximum 2.5 Replacement Zone Aggregate 500800 1:4 maximum 1 Natural Material Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

17AB Classic <strong>Retaining</strong> <strong>Wall</strong> Design HeightsCommercial <strong>Retaining</strong> <strong>Wall</strong>sDesign Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone1 Natural Material1 Natural Material1 Natural MaterialNFC 750NFC 700NFC 600NFC 550NFC 450NFC 400NFC 300NFC 300Aggregate 300Aggregate 300Aggregate 300Aggregate 3002400 1:4 maximum 5 Replacement Zone NFC 9002200 1:4 maximum 5 Replacement Zone NFC 8502000 1:4 maximum 5 Replacement Zone NFC 7501800 1:4 maximum 5 Replacement Zone NFC 7001600 1:4 maximum 5 Replacement Zone NFC 6001400 1:4 maximum 2.5 Replacement Zone NFC 4001200 1:4 maximum 2.5 Replacement Zone NFC 3001000 1:4 maximum 2.5 Replacement Zone Aggregate 500800 1:4 maximum 1 Natural Material Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

184.14 AB Junior(Allan Block) Junior200No. Per m 2 of <strong>Wall</strong> 23Approx. Weight14.7kg216 240Setback1:9.5 (6˚)Allan Block Curves DetailRemove wingsfor outside radiusAll cores and voids between units to be filledwith infill material at all timesAllan Block Corners DetailRight AnglesFirst CourseRemovelip to allownext courseSecond CourseOutside angles other than 90˚Modify adjacentunits as requiredto maintain bondAlternate Leftand Right handcorner unitsCut units to achieve desiredangle and glue in placeModify adjacentunits as requiredto maintain bondDiagrams not to scale

19AB Junior Typical <strong>Wall</strong> Section1:4 max slopeAB Capper(Short)Infill DepthLevel SlopeLow permeability top soil layerAB Junior1No structural loadswithin this line"H" Design height9.5Infill Material*1.51*Refer to page 9 when using No Finesconcrete infill materiale100mm Subsoil drain socked fall to dischargemaximum 20m centres13020mPa Concrete leveling pad130Additional extent of foundation replacement zonerequired when NFC infill material is used (refer tosection 3.4)450Foundation replacement zone <strong>com</strong>pacted roadbase 98% min RDD if requiredDiagrams not to scale

20AB Junior <strong>Retaining</strong> <strong>Wall</strong> Design HeightsResidential <strong>Retaining</strong> <strong>Wall</strong>s(Including residential subdivisions)Design Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level2400 1:4 maximum2200 1:4 maximum2000 1:4 maximum5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone1 Replacement Zone1 Natural Material1 Natural Material5 Replacement Zone5 Replacement Zone5 Replacement ZoneNFC 800NFC 750NFC 700NFC 600NFC 550NFC 500NFC 350NFC 300NFC 300Aggregate 300Aggregate 300Aggregate 300NFC 1000NFC 900NFC 8501800 1:4 maximum 5 Replacement Zone NFC 7501600 1:4 maximum 5 Replacement Zone NFC 6501400 1:4 maximum 2.5 Replacement Zone NFC 4501200 1:4 maximum 2.5 Replacement Zone NFC 3501000 1:4 maximum 2.5 Replacement Zone NFC 300800 1:4 maximum 1 Replacement Zone Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

21AB Junior <strong>Retaining</strong> <strong>Wall</strong> Design HeightsCommercial <strong>Retaining</strong> <strong>Wall</strong>sDesign Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone1 Replacement Zone1 Natural Material1 Natural MaterialNFC 800NFC 750NFC 700NFC 600NFC 550NFC 500NFC 350NFC 300NFC 300Aggregate 300Aggregate 300Aggregate 3002400 1:4 maximum 5 Replacement Zone NFC 10002200 1:4 maximum 5 Replacement Zone NFC 9002000 1:4 maximum 5 Replacement Zone NFC 8501800 1:4 maximum 5 Replacement Zone NFC 7501600 1:4 maximum 5 Replacement Zone NFC 6501400 1:4 maximum 2.5 Replacement Zone NFC 4501200 1:4 maximum 2.5 Replacement Zone NFC 3501000 1:4 maximum 2.5 Replacement Zone NFC 300800 1:4 maximum 1 Replacement Zone Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

224.15 AB Stones(Allan Block) Stones200No. Per m 2 of <strong>Wall</strong> 11.5435305Approx. WeightSetback31.25kg1:4.75 (12˚)Allan Block Curves DetailRemove wingsfor outside radiusAll cores and voids between units to be filledwith infill material at all timesAllan Block Corners DetailRight AnglesFirst CourseRemovelip to allownext courseSecond CourseOutside angles other than 90˚Modify adjacentunits as requiredto maintain bondAlternate Leftand Right handcorner unitsCut units to achieve desiredangle and glue in placeModify adjacentunits as requiredto maintain bondDiagrams not to scale

23AB Stones Typical <strong>Wall</strong> Section1:4 max slopeInfill DepthAB CapperLevel SlopeLow permeability top soil layerAB Stones1No structural loadswithin this line"H" Design height4.7Infill Material*1.51*Refer to page 9 when using No Finesconcrete infill materiale100mm Subsoil drain socked fall to dischargemaximum 20m centres15020mPa Concrete leveling pad150Additional extent of foundation replacement zonerequired when NFC infill material is used (refer tosection 3.4)600Foundation replacement zone <strong>com</strong>pacted roadbase 98% min RDD if requiredDiagrams not to scale

24AB Stones <strong>Retaining</strong> <strong>Wall</strong> Design HeightsResidential <strong>Retaining</strong> <strong>Wall</strong>s(Including residential subdivisions)Design Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level2400 1:4 maximum2200 1:4 maximum2000 1:4 maximum5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Natural Material2.5 Natural Material1 Natural Material1 Natural Material1 Natural Material5 Replacement Zone5 Replacement Zone5 Replacement ZoneNFC 600NFC 550NFC 500NFC 450NFC 400NFC 300Aggregate 700Aggregate 300Aggregate 300Aggregate 300Aggregate 300Aggregate 300NFC 750NFC 675NFC 6251800 1:4 maximum 5 Replacement Zone NFC 5501600 1:4 maximum 5 Replacement Zone NFC 4751400 1:4 maximum 2.5 Replacement Zone Aggregate 7001200 1:4 maximum 2.5 Replacement Zone Aggregate 6001000 1:4 maximum 2.5 Replacement Zone Aggregate 500800 1:4 maximum 1 Natural Material Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

25AB Stones <strong>Retaining</strong> <strong>Wall</strong> Design HeightsCommercial <strong>Retaining</strong> <strong>Wall</strong>sDesign Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone1 Natural Material1 Natural Material1 Natural MaterialNFC 600NFC 550NFC 500NFC 450NFC 400NFC 300Aggregate 700Aggregate 600Aggregate 500Aggregate 400Aggregate 300Aggregate 3002400 1:4 maximum 5 Replacement Zone NFC 7502200 1:4 maximum 5 Replacement Zone NFC 7002000 1:4 maximum 5 Replacement Zone NFC 6501800 1:4 maximum 5 Replacement Zone NFC 5501600 1:4 maximum 5 Replacement Zone NFC 5001400 1:4 maximum 2.5 Replacement Zone Aggregate 7001200 1:4 maximum 2.5 Replacement Zone Aggregate 6001000 1:4 maximum 2.5 Replacement Zone Aggregate 500800 1:4 maximum 1 Natural Material Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

264.16 AB Three(Allan Block) Three200No. Per m 2 of <strong>Wall</strong> 11.5435305Approx. WeightSetback31.25kg1:19 (3˚)Allan Block Curves DetailRemove wingsfor outside radiusAll cores and voids between units to be filledwith infill material at all timesAllan Block Corners DetailRight AnglesFirst CourseRemovelip to allownext courseSecond CourseOutside angles other than 90˚Modify adjacentunits as requiredto maintain bondAlternate Leftand Right handcorner unitsCut units to achieve desiredangle and glue in placeModify adjacentunits as requiredto maintain bondDiagrams not to scale

27AB Three Typical <strong>Wall</strong> Section1:4 max slopeInfill DepthAB CapperLevel SlopeLow permeability top soil layerAB Three1No structural loadswithin this line"H" Design height19Infill Material*1.51*Refer to page 9 when using No Finesconcrete infill materiale100mm Subsoil drain socked fall to dischargemaximum 20m centres15020mPa Concrete leveling pad150Additional extent of foundation replacement zonerequired when NFC infill material is used (refer tosection 3.4)600Foundation replacement zone <strong>com</strong>pacted roadbase 98% min RDD if requiredDiagrams not to scale

28AB Three <strong>Retaining</strong> <strong>Wall</strong> Design HeightsResidential <strong>Retaining</strong> <strong>Wall</strong>s(Including residential subdivisions)Design Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level2400 1:4 maximum2200 1:4 maximum2000 1:4 maximum5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Natural Material1 Natural Material1 Natural Material1 Natural Material5 Replacement Zone5 Replacement Zone5 Replacement ZoneNFC 850NFC 750NFC 700NFC 600NFC 550NFC 450NFC 300NFC 300Aggregate 300Aggregate 300Aggregate 300Aggregate 300NFC 1000NFC 900NFC 8001800 1:4 maximum 5 Replacement Zone NFC 7501600 1:4 maximum 5 Replacement Zone NFC 6501400 1:4 maximum 2.5 Replacement Zone NFC 4501200 1:4 maximum 2.5 Replacement Zone NFC 3501000 1:4 maximum 2.5 Replacement Zone NFC 300800 1:4 maximum 1 Replacement Zone Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

29AB Three <strong>Retaining</strong> <strong>Wall</strong> Design HeightsCommercial <strong>Retaining</strong> <strong>Wall</strong>sDesign Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Natural Material1 Natural Material1 Natural Material1 Natural MaterialNFC 850NFC 750NFC 700NFC 600NFC 550NFC 450NFC 300NFC 300Aggregate 300Aggregate 300Aggregate 300Aggregate 3002400 1:4 maximum 5 Replacement Zone NFC 10002200 1:4 maximum 5 Replacement Zone NFC 9002000 1:4 maximum 5 Replacement Zone NFC 8001800 1:4 maximum 5 Replacement Zone NFC 7501600 1:4 maximum 5 Replacement Zone NFC 6501400 1:4 maximum 2.5 Replacement Zone NFC 4501200 1:4 maximum 2.5 Replacement Zone NFC 3501000 1:4 maximum 2.5 Replacement Zone NFC 300800 1:4 maximum 1 Replacement Zone Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

304.17 AB Vertical(Allan Block) Vertical200No. Per m 2 of <strong>Wall</strong> 11.5435305Approx. WeightSetback31.25kg1:40 (14˚)Allan Block Curves DetailRemove wingsfor outside radiusAll cores and voids between units to be filledwith infill material at all timesAllan Block Corners DetailRight AnglesFirst CourseRemovelip to allownext courseSecond CourseOutside angles other than 90˚Modify adjacentunits as requiredto maintain bondAlternate Leftand Right handcorner unitsCut units to achieve desiredangle and glue in placeModify adjacentunits as requiredto maintain bondDiagrams not to scale

31AB Vertical Typical <strong>Wall</strong> Section1:4 max slopeInfill DepthAB CapperLevel SlopeLow permeability top soil layerAB Vertical1No structural loadswithin this line"H" Design height40Infill Material*1.51*Refer to page 9 when using No Finesconcrete infill materiale100mm Subsoil drain socked fall to dischargemaximum 20m centres15020mPa Concrete leveling pad150Additional extent of foundation replacement zonerequired when NFC infill material is used (refer tosection 3.4)600Foundation replacement zone <strong>com</strong>pacted roadbase 98% min RDD if requiredDiagrams not to scale

32AB Vertical <strong>Retaining</strong> <strong>Wall</strong> Design HeightsResidential <strong>Retaining</strong> <strong>Wall</strong>s(Including residential subdivisions)Design Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level2400 1:4 maximum2200 1:4 maximum2000 1:4 maximum5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone1 Natural Material1 Natural Material1 Natural Material5 Replacement Zone5 Replacement Zone5 Replacement ZoneNFC 900NFC 800NFC 750NFC 650NFC 600NFC 500NFC 350NFC 300NFC 300Aggregate 300Aggregate 300Aggregate 300NFC 1050NFC 950NFC 8501800 1:4 maximum 5 Replacement Zone NFC 8001600 1:4 maximum 5 Replacement Zone NFC 7001400 1:4 maximum 2.5 Replacement Zone NFC 4501200 1:4 maximum 2.5 Replacement Zone NFC 3501000 1:4 maximum 2.5 Replacement Zone NFC 300800 1:4 maximum 1 Replacement Zone Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

33AB Vertical <strong>Retaining</strong> <strong>Wall</strong> Design HeightsCommercial <strong>Retaining</strong> <strong>Wall</strong>sDesign Height ‘H’(mm)Surface SlopeSurcharge Load(kPa)Foundation MaterialInfill MaterialInfill Material Depth(mm)2600 Level2400 Level2200 Level2000 Level1800 Level1600 Level1400 Level1200 Level1000 Level800 Level600 Level400 Level5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone2.5 Replacement Zone1 Natural Material1 Natural Material1 Natural MaterialNFC 900NFC 800NFC 750NFC 650NFC 600NFC 500NFC 350NFC 300NFC 300Aggregate 300Aggregate 300Aggregate 3002400 1:4 maximum 5 Replacement Zone NFC 10502200 1:4 maximum 5 Replacement Zone NFC 9502000 1:4 maximum 5 Replacement Zone NFC 8501800 1:4 maximum 5 Replacement Zone NFC 8001600 1:4 maximum 5 Replacement Zone NFC 7001400 1:4 maximum 2.5 Replacement Zone NFC 4501200 1:4 maximum 2.5 Replacement Zone NFC 3501000 1:4 maximum 2.5 Replacement Zone NFC 300800 1:4 maximum 1 Replacement Zone Aggregate 400600 1:4 maximum 1 Natural Material Aggregate 300400 1:4 maximum 1 Natural Material Aggregate 300NFC denotes the use of No Fines Concrete. Where NFC is to be used, you must ensure that the natural site material has an internal friction angle of 30˚ or more.These designs are not suitable for clay sites.

5.0 Typical Detailsfor Creating Steps and Stairs34Install a paver with bullnoseedge to create stair treadInstall two retainingwall units back to backto create stepUse mass concrete or<strong>com</strong>pacted earth at rearof wall units to providesolid foundation forsubsequent stair treadsInstall mass concrete levelling padto underside of first stepInstall a paver with bullnoseedge to create stair treadInstall a retaining wall unitwith required overlap tocreate desired step widthUse mass concrete or<strong>com</strong>pacted earth at rearof wall units to providesolid foundation forsubsequent stair treadsInstall mass concrete levelling padto underside of first stepInstall a paver with bullnoseedge to create stair treadInstall retaining wall unitswith required distance betweento create desired step widthGUse mass concrete to rearand underside of wall unitsto provide solid foundationfor subsequent stair treadsRPermissable Step Dimensions(in accordance with BCA requirements)R G 2R + GMaximumMinimumMaximumMinimumMaximumMinimum190 115355 240700 550Diagrams not to scale

6.0 Overviewof Geogrid Reinforced <strong>Wall</strong>s35Reinforced soil retaining walls are essentially gravity wall structures that depend on the mass of the reinforced soil zone behind theretaining wall units to resist destabilising forces due to retained soil and surcharge loadings.The AB range of masonry segmental blocks in <strong>com</strong>bination with polyester Geogrid provides a proven aesthetically pleasing and costeffective method of constructing high retaining walls.Geogrid provides connection of the reinforced soil to the Adbri Masonry segmental retaining wall blocks. The <strong>com</strong>bination of retainingwall blocks with Geogrid has the capacity to form a mechanical connection.Geogrid was chosen as the preferred reinforcing element because of it’s light, flexible nature, ease of handling, superior creep resistanceand long term load carrying capacity <strong>com</strong>pared to other products on the market, and it’s maintained strength/creep characteristics whensubjected to elevated surface temperatures <strong>com</strong>monly experienced in block retaining system applications.The <strong>com</strong>bination of retaining wall blocks with Geogrid has been accepted by major construction authorities in Australia for use in structureswith a design life of 100 years.<strong>Retaining</strong> wall design software is available to engineers to allow the optimum use of Geogrid and retaining wall products. We can also providecontracting services for all types of retaining wall projects.AB Classic, AB Stones and AB Three are all R57 approved products.Reinforced <strong>Wall</strong> Cross SectionSetback variesSurchargeLow permeability layerGranular fillReinforced soilOther grid layersExcavationHGeo synthetic grid2nd grid layerRetained soilL1st grid layereFoundation material150mm min. granular fill or concrete levelling padas detailed for each block typeDiagrams not to scale