| | #1 |

| BHPian | |

| |

| |

| | #2 |

| BANNED Join Date: Oct 2008 Location: Hyderabad

Posts: 221

Thanked: 12 Times

| |

| |

| | #3 |

| BHPian Join Date: Jan 2009 Location: Bangalore

Posts: 39

Thanked: 89 Times

| |

| |

| | #4 |

| BHPian | |

| |

| | #5 |

| Team-BHP Support  Join Date: Feb 2004 Location: Bombay

Posts: 24,073

Thanked: 34,239 Times

| |

| |

| | #6 |

| BHPian | |

| |

| | #7 |

| Senior - BHPian | |

| |

| | #8 |

| Team-BHP Support  | |

| |

| | #9 |

| Senior - BHPian | |

| |

| | #10 |

| Senior - BHPian | |

| |

| | #11 |

| BHPian | |

| |

| |

| | #12 |

| Team-BHP Support  Join Date: Feb 2004 Location: Bombay

Posts: 24,073

Thanked: 34,239 Times

| |

| |

| | #13 |

| Senior - BHPian | |

| |

| | #14 |

| Senior - BHPian | |

| |

| | #15 |

| Senior - BHPian | |

| |

|

Most Viewed

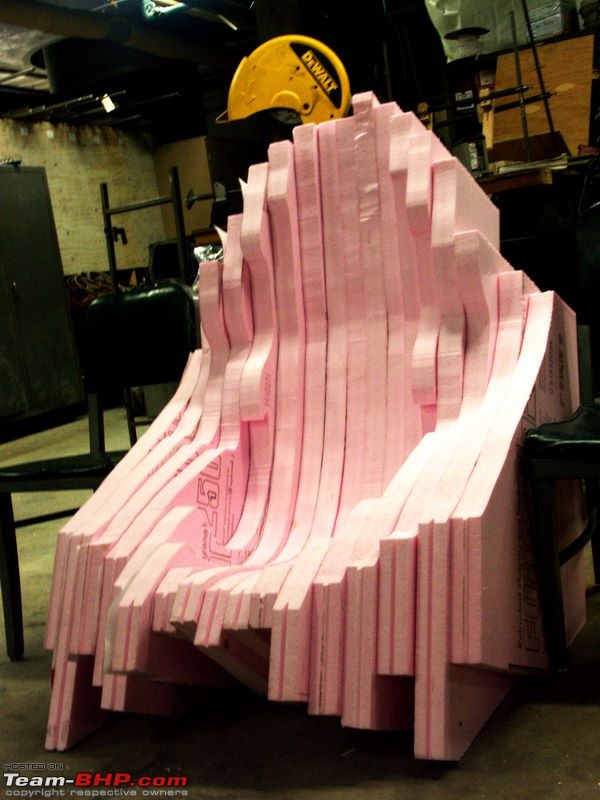

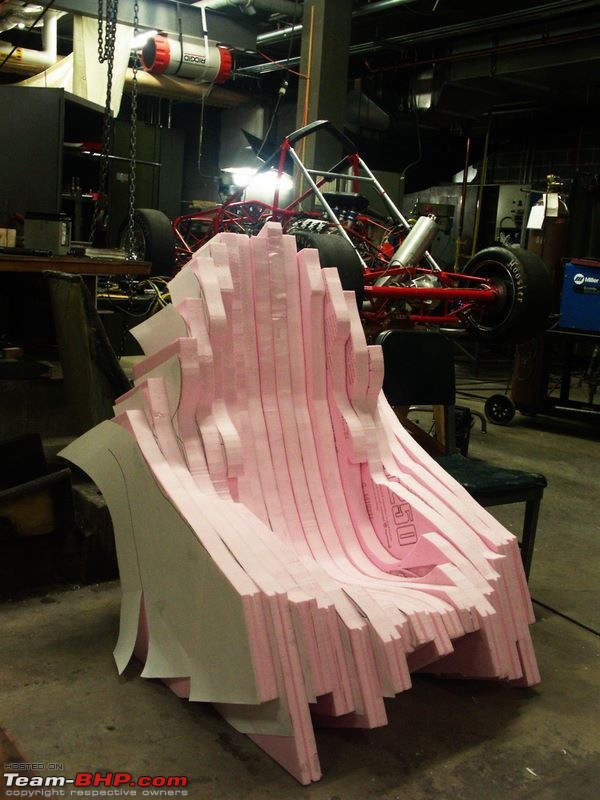

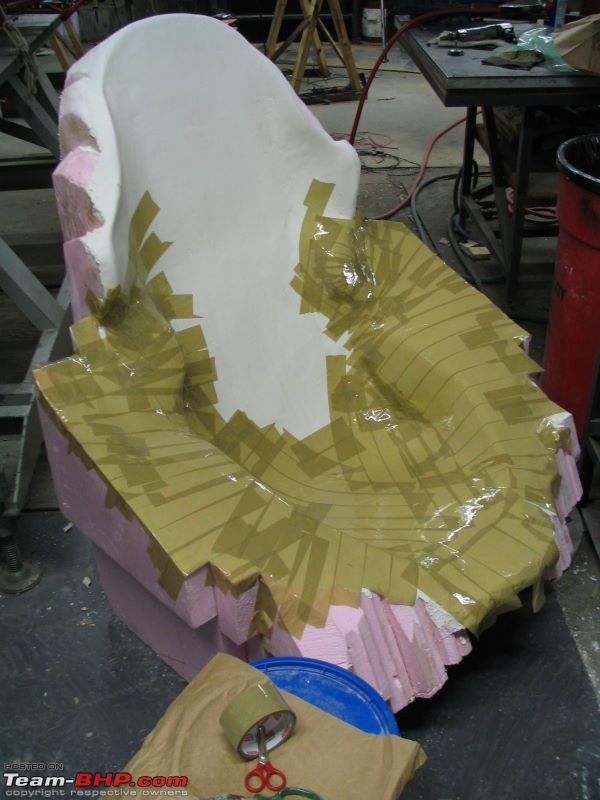

I am back with a new project this time around.

I am back with a new project this time around.